To empowering build smart logistics scenarios,

LeapFive Technology launched a BF2-based logistics and warehousing management solution

Currently, in the warehouse logistics outsourcing business, due to the various modes of customer operation (B2B and B2C), some customers have many types of goods in the warehouse and large number of stores or end-users, resulting in a complex relationship between goods and orders, the traditional warehouse operation and management mode relies heavily on personnel experience and workload, and operating costs are rising sharply. Therefore, we urgently need to improve manual efficiency through WMS system in collaboration with IoT and AI.

Meanwhile, logistics and warehousing-related assets are mainly leased, supplemented by procurement. Digital and intelligent improvement programs need to consider engineering installation and relocation costs simultaneously. For leased warehouses and logistics carriers, it is necessary to consider together whether sunk costs will be formed when the relevant assets are transferred, and different solution strategies and response products should be formulated for different operation modes.

From the product and R&D perspective, solutions can be designed and implemented for two directions: one is the collection of key information to support operations (perception technology), and the other is to assist personnel operations to improve efficiency (convenient interaction):

1. Achieving the collection of storage and transportation data through the tracking and status monitoring of (standardized) carriers to support the analysis of operational big data; using location and sensor feedback information to automate the processing of some management functions.

2. Reducing the probability of manual judgment and errors during manual operation through automatic identification of carriers and goods.

3. Easier access to information, optimized human-machine interaction, improved convenience of manual operation, reduced query, communication, and confirmation time.

Application

Tracking and perception of carriers

• The use of reusable turnover boxes enables the circulation of goods between warehouses and stores.

• The use of reusable pallets enables the circulation of goods between warehouses and suppliers/factories.

• The use of on-board gateways enables the monitoring of carriers’ location, load weight, acceleration, door opening and closing, and other statuses and events.

• Smart Bluetooth tags with additional battery power in the turnover boxes and pallets are equipped with various sensors (temperature, humidity, box opening and closing, etc.), which enable the monitoring of the status and events of the carriers.

• The NFC ID built into the turnover boxes is used for accurate identification by smart sorting carriers and automated shipping equipment.

• Using intelligent gateways that support AoA positioning, the Bluetooth tags of various carriers can be accurately and real-time located. At the same time, it supports the indoor high-precision positioning of intelligent sorting carts and monitors the cargo information inside the turnover boxes through the weight and image sensors built into the carts.

• The intelligent gateway is easy to deploy and dismantle and can be easily powered and networked.

Convenient interaction during warehouse operations

• By monitoring the position of the Bluetooth tag attached to the carrier, functions such as one-click receipt, one-click delivery, and inventory checking can be achieved.

• Electronic shelf labels are installed on the shelves to accurately prompt the picker to pick the type and quantity of goods, and the flashing lights replace paper documents for confirmation.

• The intelligent sorting small car automatically associates the turnover box with the (customer) order, eliminating the need for secondary sorting and supports audio and video prompts to prevent misoperation.

• AGV is used to shuttle the sorting small car between the packing area and the shelves, allowing the picker to focus on picking.

LeapFive Solutions

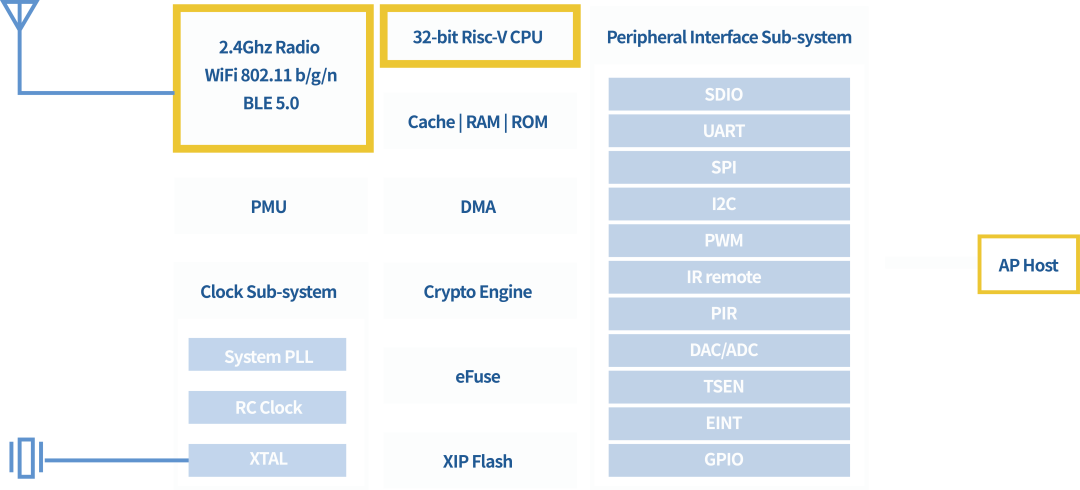

BF2 is a highly integrated Wi-Fi/BLE chip designed for low-cost and low-power wireless IoT applications. Its core technology comes from the world’s first Wi-Fi/BLE combination chip design based on RISC-V.

In LeapFive logistics and warehousing management solution, BF2 is mainly used for carriers tracking, sensing interaction, and can be directly applied to smart tags and smart shelf labels and other device terminals.

Carriers tracking-related

BF2 is a high-integration Wi-Fi/BLE chip designed for wireless connectivity applications on the IoT with ultra-low cost and low power consumption. Its core is derived from the world’s first Wi-Fi/BLE combination function chip design based on RISC-V.

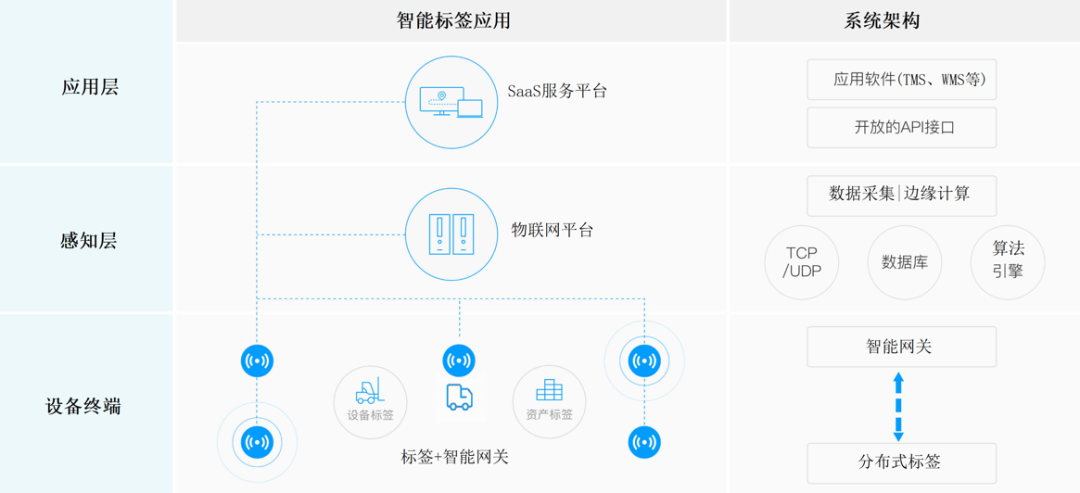

By using Bluetooth smart tags/shelves tags, smart gateways, and related supporting systems, combined with GPS and Bluetooth AoA high-precision positioning technology, seamless connection of location information can be achieved in transportation and warehousing scenarios. The position data is wirelessly transmitted to the management system for graphical display, data statistics, and real-time monitoring, which facilitates asset management and traceability and can effectively reduce asset and cargo loss rates. In indoor environments such as warehouses and stores, accurate identification of goods location can be achieved by installing smart tags on carriers, which can be combined with WMS system to realize functions such as one-click receipt, one-click delivery, automate the management of inbound and outbound, reduce the time spent on scanning goods and data entry, and facilitate automated inventory taking of goods by WMS system, reducing reliance on manual labor and improving operational efficiency.

Smart Tags (Bluetooth)

By using the LeapFive BF2 chip on smart tags, it is possible to achieve Bluetooth and Wi-Fi connections, including front-end data acquisition processing, temperature and humidity, light, pressure, as well as the state of goods (such as whether the turnover box has been opened, how many times it has been opened, etc.).

The Main Functions:

• Equipped with built-in Bluetooth antenna

• Built-in large capacity button battery, with a battery life of ≥6 months

• Supports Bluetooth 5.0 and Bluetooth tag function

• Supports NFC tag function

• Supports temperature and humidity monitoring function

• Supports atmospheric pressure monitoring function

• Supports open box monitoring function

• Supports acceleration monitoring function

• Sensor data is broadcasted every 15 seconds

• Operating temperature: -30℃~+55℃

• Supports real-time positioning through Bluetooth AOA with the gateway

• Optional charging battery, supports NFC charging

• Supports external electronic ink screen

• Supports structural adaptation for various turnover boxes

Portable Interaction Related

Currently, some warehouses still use paper documents for centralized sorting and secondary sorting. Its advantages are low dependence on the backend system, but it requires a large amount of manual work, high experience requirements, and the need to set up three positions: centralized sorting, secondary sorting, and packaging and shipping. The number of manual workers is large (accounting for more than 50%). By strengthening WMS + AI + IoT backend support, the optimal sorting strategy can be selected to complete the sorting task at one time, reducing the process of manual identification and confirmation:

• Reduce the requirements for personnel, and they can be put into work as soon as they are hired to cope with the high turnover rate of outsourced personnel.

• Improve employee efficiency and reduce ineffective work (detours, repeated confirmations, manual information processing, error correction, etc.).

• The lightweight asset operation mode requires low transformation cost for leased assets, low migration cost, and high integration degree and easy disassembly of additional intelligent equipment.

Electronic Shelf Label (ESL)

The BF2 chip is used on the electronic shelf label to link with the smart tag. When a turnover box is placed on the shelf, it will be automatically bound and linked, allowing us to know what turnover box is placed on the shelf, as well as what goods are placed in the turnover box, thus realizing digitization and intelligence.

The Main Functions:

• Bluetooth or CAN bus connection to the gateway

• Battery or gateway DC power supply

• The structural design can be installed on the shelf or smart sorting carriers

• Supports e-ink screen (below 3 inches) + indicator light indication

• Supports quick response button turn-off

• Operating temperature: 0℃ ~ +40℃

LeapFive Technology’s BF2 chip has been deeply integrated with logistics and warehouse management. In the future, with the development of various technologies and applications such as sensors, image recognition, edge computing, and machine learning, digital warehousing and logistics with full-process perception can gradually be realized, seamlessly integrated with automated intelligent equipment, and AI can be used to enhance resource utilization and process efficiency, ultimately evolving towards unmanned operations. As an important part of digital infrastructure, the digitization and intelligence of logistics will inevitably follow the trend of industry intelligence and low-carbon environmental protection.